Tomato paste processing equipment automatic tomato paste production

line turkey

Ketchup processing line is mainly used in large-scale fruit

processing field. Ketchup factory can make red mature tomatoes into

ketchup. It not only retains more original tomato flavor, 100% no

additives, but also is convenient for storage and transportation.

We can sell ketchup to small ketchup factories, and we can also use

ketchup to produce ketchup to enrich our final products. Ketchup

processing line has many tomato processing equipment with different

functions, which together form a ketchup processing line.

Tomato bubble washing machine

Tomato bubble washing machine is also called tomato floating

washing machine. Equipped with spray cleaning device. Driven by the

water flow in the conveying tank, the tomatoes follow the water

flow into the next process. The ingenious double-layer design makes

the sand and stone precipitate to the bottom layer and discharge.

Tomato preheating machine

Before crushing tomatoes, we need to preheat them, pour washed and

dehydrated tomatoes into boiling water and bleach them for 2 to 3

minutes to soften the pulp for crushing and pulping.

Tomato crusher

The tomato press is suitable for pressing tomatoes and other

berries. It can also crush pre boiled and softened tomatoes with a

crushing particle size of 5-8mm. At the same time, the tomato

crushing is completed, the cavity is completely closed, the

sanitary conditions are better than ordinary crushers, and the

noise is low.

Crushing tomato buffer tank

It can temporarily buffer 5000L crushed tomatoes and do any harm to

human body. Due to the use of 304 food grade stainless steel.

Brief Information:

| Product Name | 2-50T/H Tomato/Carrot processing line |

| Processing line type | Complete turn-key project |

| Juice yield | ≥ 90% |

| Final product brix | 7-12brix(for juice) |

| Voltage | 380V 50Hz/110V 60hz/415V 50Hz |

| Power consumption(Kw) | energy saving type, about 100-500kw, |

| Operator needed | About 6-20persons |

| Cooling water consumption | About 80-300M3 |

| Steam consumption | About 300-5000T/H, |

| Factory space needed | About 500-5000Sqm |

| Warranty | 12 months |

Features of Tomato/Carrot processing line

1. Flexible configuration to make the line, according to different

requirements for the end products, some exact equipments with

different functions are flexible chosen, for example:

debitterizing, deacidification, oil refiner, evaporation etc.

2. According to different investment value and product structure,

client can require average, middle level or high level processing

equipments.

3. End product with pure flavor, bright color, and high output

percentage;

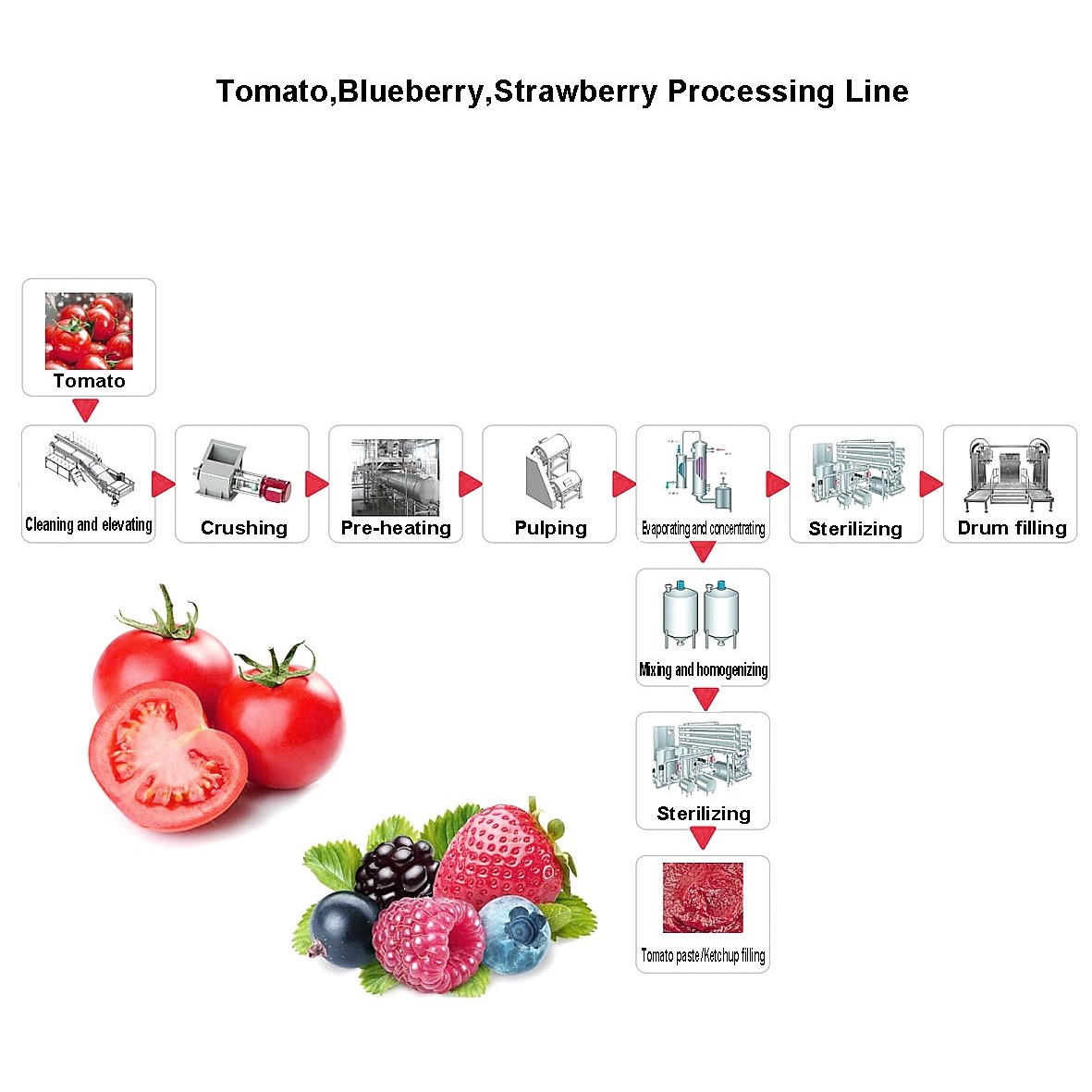

Production line machine composition:

fruit collecting and feeding;

tomato washing machine;

tomato sorting machine;

cold break tomato pulping machine;

tomato puree storage tank;

tubular tomato pre-heating machine ;

tomato refining machine;

tomato paste/sauce/ketchup evaporator;

tomato paste/sauce/ketchup storage tank;

tomato paste/sauce/ketchup sterilizer;

tomato paste/sauce/ketchup aseptic filling machine.

Specifications:

| Brand Name: | Shanghai Beyond |

| Model Number: | BY-TC |

| Capacity | 2-50T/H |

| Raw material | Fresh tomato / carrot/tomato paste |

| End product | NFC fresh tomato juice, concentrated tomato paste, concentrated

carrot juice, tomato ketchup, tomato sauce, tomato puree, etc. |

| Juice yield | ≥ 90% |

| Final product brix | 7-12brix(for juice) |

| Package for end product | Aseptic large bag in drum/ glass bottle/PET bottle, Roof type

carton box/ brick shape carton |

| Certification: | ISO9001/CE/SGS |

| Main material for machines | SUS304 or SUS316 |

Tomato pulping machine

The tomato pulping machine is suitable for the separation of tomato

pulp residue after crushing and precooking. The first channel is

coarse pulping and the second channel is fine pulping. The

equipment has the advantages of reasonable structure, high

efficiency, high pulp yield, fast separation speed, large

production capacity and good stability.

Ketchup vacuum continuous evaporator

Ketchup vacuum continuous evaporator is suitable for continuous

evaporation of ketchup and other fluid materials under vacuum and

low temperature conditions to achieve the effect of concentrating

into ketchup.

Ketchup UHT sterilizer

This ketchup UHT integrates heating, sterilization, cooling and

heat recovery, and can reflect the real production data. The four

layer shell structure is adopted, the thermal medium or refrigerant

is distributed in the inner and outer layers, and the feed liquid

passes through the middle layer.

The inner and outer layers are heated or cooled, and the heat

exchange area is large; The specific heat capacity of water is

large, the sterilization temperature is stable and uniform, and the

sterilization effect is good; PLC automatic control is adopted, and

the sterilization temperature parameters can be set freely

according to different materials.

Aseptic bag drum filling machine

Aseptic packaging of concentrated ketchup and other liquids, the

products can be stored at room temperature for more than one year,

which can save the cost and risk of low-temperature refrigerated

transportation.

CIP cleaning system

The unique water flow conveying design can not only greatly improve

the conveying efficiency, but also will not damage the tomato skin.

A wide range of applications, tomato sauce processing plant is also

suitable for the production of chili sauce.

CIP cleaning system is adopted, which does not need to disassemble

the pipeline of ketchup production plant, which is convenient for

cleaning and maintenance and reduces the labor intensity of

workers.

The two effect concentrator evaporates at the same time, and the

secondary steam can be used. Compared with the single effect

concentrator, the total energy consumption is reduced.

The automatic ketchup production line provided by beyond is mainly

fresh and mature tomatoes. After cleaning, upgrading, sorting,

crushing, beating, concentration and sterilization, they are filled

into sterile ketchup products after aseptic filling.

Main features of automatic ketchup making machine:

1. Simple operation, low noise and long service life.

2. The machine adopts food grade stainless steel parts and

materials, which is easy to clean.

3. It can meet the different needs of customers with different

capacities, and has the advantages of large output, high

efficiency, energy saving, safety, health and no pollution.

4. The ketchup production machine meets the national standard and

is safe and reliable.

Production process for making ketchup:

Fresh tomato - tomato cleaning - sorting - impurity removal -

crushing - tomato pulping - vacuum concentration - paste

sterilization - filling.

Ketchup is a kind of condiment. It is sweet and delicious. It is

deeply loved by people. It is a must-have in many restaurants. But

how to make ketchup, as a professional food processing and

production designer. Beyond offers a complete production line of

ketchup making machine, from tomato cleaning to final filling

machine.

The ketchup production line is customized, developed and

manufactured according to the needs of customers. From pre-sales

design to manufacturing, re transportation and installation,

customers can track and understand and master the latest product

information. The ketchup production line can fully meet the

production needs of customers, quickly obtain the competitive

advantage of goods in the local market and obtain long-term and

reliable production benefits.