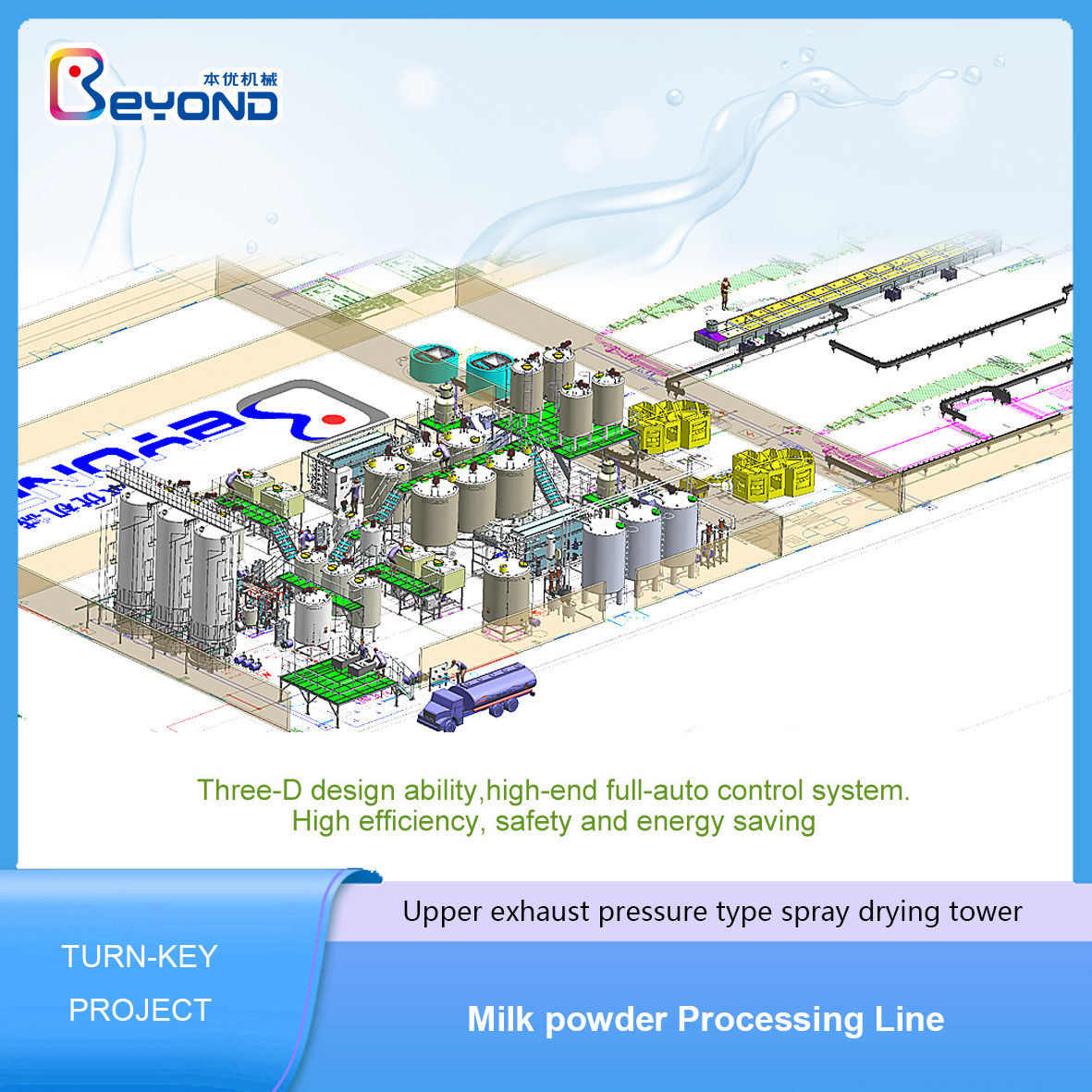

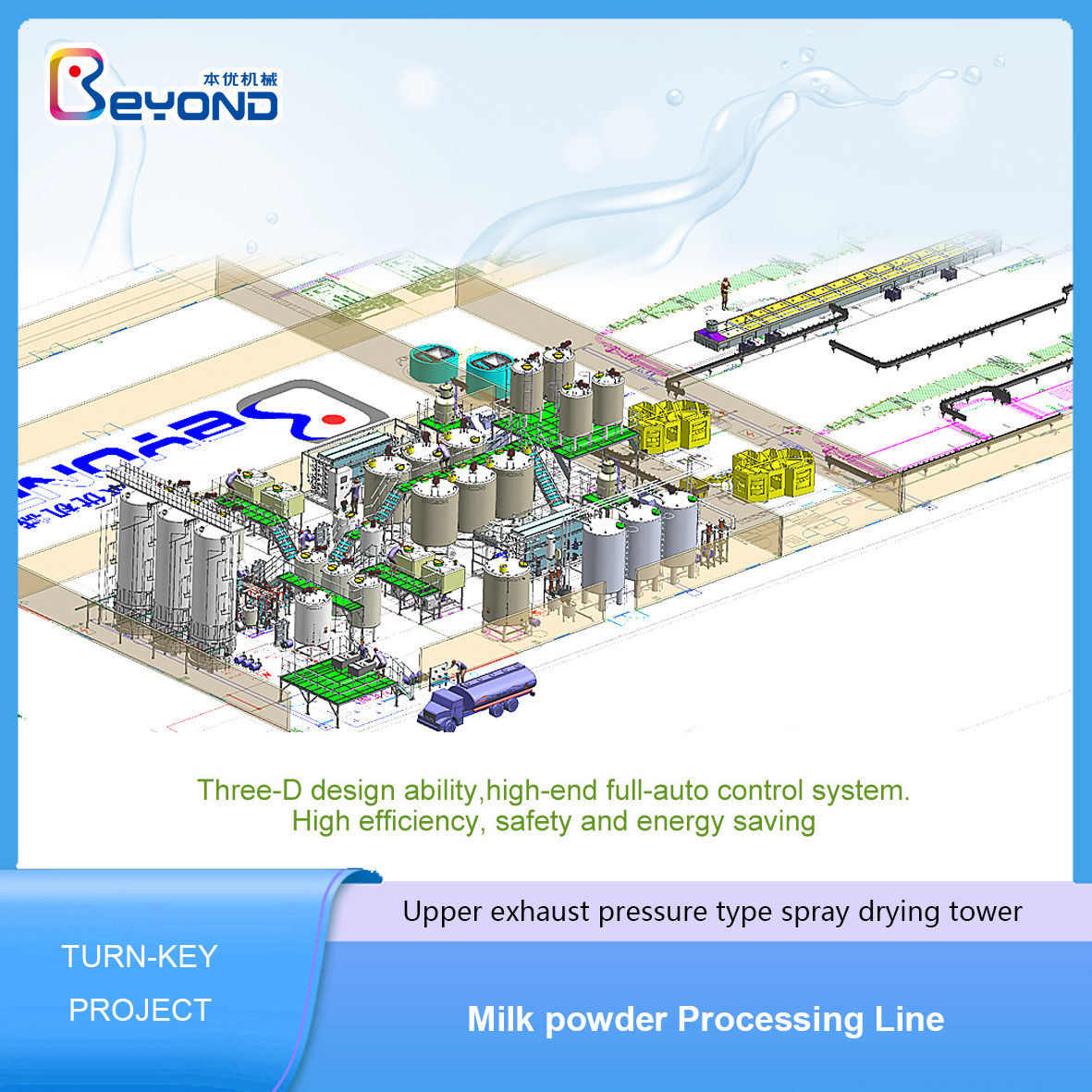

Milk powder plant for sale small scale milk powder plant powder

milk processing plant

The milk powder production line can mechanically produce milk

powder, which is a processed dairy product that evaporates milk to

dry under controlled conditions. In addition to reducing weight and

volume, drying also extends the shelf life of milk. The initial

solids content of milk is between 7.5% and 12%, and the final

solids content is between 96% and 97.5% after drying.

This is achieved by:

Multistage evaporator

Secondary/tertiary dryer

Process of milk powder production line

The combination of multi effect evaporator, spray dryer and fine

particle recycling system, as well as the use of "vibrating

fluidized bed dryer", produces powders with very high solubility,

called instant powders.

The milk powder production line also provides a lecithin system

integrated with the milk powder factory to produce whole milk

powder. The system is used to produce high-quality whole milk

powder. The milk powder production line ensures to provide the most

energy-saving factory and produce the highest quality instant

powder.

Products of milk powder production line

Skim milk powder, whole milk powder, baby food, dairy whitening

agent.

Features of milk powder production line

The production process of milk powder and infant formula requires a

lot of detailed technology. From milk, sometimes even

reconstituted, the dry final product is made in the form of powder.

For value-added products such as infant formula, it is important to

add ingredients.

Beyond Machinery provides value-added solutions for most production steps, which

have one or more of the following advantages.

1) Better quality

The main reason is that the processing time is shorter and the

processing temperature is lower

2) Reduce energy use

Recover energy as much as possible due to good engineering

principles

3) Reduce investment

Our design is based on extensive experience in this field.

Therefore, we only invest in absolutely needed equipment. If

possible, we combine the ergonomic design of production steps and

maintenance tasks. Our design engineers have many years of factory

operation experience. We design a factory suitable for all

capabilities. Design the milk receiving plant with minimal capital

expenditure. We prefer to provide one unloading system for the two

unloading areas to optimize the utilization of equipment.

Operation process of milk powder production line

Truck 1 arrives at the first station, connects and performs quality

control.

Next, truck 1 will begin unloading milk.

During this period, truck 2 comes to the second compartment and

starts to prepare the hoses and perform quality control.

When truck 1 finishes unloading milk,

Truck 2 will automatically begin unloading.

Truck 1 removes the hose in order to make room for a new truck.

We design the unloading time to be less than or equal to the

combined connection and check time.

For more information about the organizer function, please visit the

dedicated efficient milk receiving page.

We provide an energy-saving solution from raw milk storage to pre

evaporation (including pre evaporation).

Milk clarification

Heat treatment (low, medium and high heat)

Integrated pasteurization

Product pre concentration

Cooling of pre concentrate, condensate and cream

These 5 processes are further optimized to use less energy. This is

mainly possible because we maximize the reuse of energy stored in

the product. If the raw milk temperature is lower than 5 ° C, we do

not need any chilled water for normal operation.

Benyou Machinery has designed a high concentration device for the

dairy product production line, which has an integrated feeding and

recovery system. This design principle ensures high energy recovery

and minimum production loss.

Features and advantages:

1. Processing capacity can be ranged from 1T/Day to 100T/Day.

2. High standard design, manufacture and project installation

requirements, which guarantee the first-class finish products in

the dairy processing line.

3. PLC control the whole production line, saving labor force and

facilitate production management.

4. Full-auto CIP cleaning, to ensure whole production line

equipments meet food sanitary safety requirements.

5. Whole line with features as high level automatic, low labour

intensity, easy operation, safe function and low operation cost.

6. Whole line adopt sanitary design, can be cleaned thoroughly,

with high level sanitation.

Equipment list and technical details:

| Flow No. | Name | Size | Main technology parameter | Unit | QTY |

| A | Milk collection and storage unit |

| A-1 | chiling tank | V=3000L | SUS304 stainless steel,dimple pad jacket,attached with compressor,

temperature automatic control, sealed manhole, breath valve, CIP

spray ball, entire frame support | pcs | 2 |

| A-2 | milk transport tank | V=5000L | SUS304 stainless steel, PU insulation, devided to 2 chambers,

saddel type legs, with two manholes, spray balls, product outlet

etc | pcs | 1 |

| A-3 | loadometer | | maximum weighing 15T | PCS | 1 |

| A-4 | Milk pump | 10T/H | SUS304 stainless steel, pump lift is 24 meters, mechanical seal | Set | 1 |

| A-5 | Twin piping filter | 5T/H | SUS304 stainless steel, two pipes, stainless steal filter element

100 mesh | Set | 1 |

| A-6 | Milk cooling tank | 3000L |

SUS304 stainless steel,dimple pad jacket,equipped with

compressor,temperature automatic control,sealed manhole, breath

valve, CIP spray ball, entire frame support | Set | 2 |

| A-7 | Milk pump | 3T/H | SUS304 stainless steel, pump lift is 24 meters, mechanical seal | Set | 1 |

| A-8 | Milk pump | 10T/H | SUS304 stainless steel, pump lift is 24 meters, mechanical seal | Set | 1 |

| A-9 | powder and liquid mixer | 10T/h | SUS304,horizontal type | set | 1 |

| B | pasteurizing unit |

| B-1 |

plate pasteurizer | 1T/H | SUS304 stainless steel, plate type, product inlet temperature 5℃,

cream separator temperature 55℃,homogenizer temperature 65℃,

pasteurization temperature 72-95℃,15S,output temperature

5℃,semi-automatic control | Set | 1 |

| B-2 | High pressure homogenizer | 1T/H | 25MPa, including starting cabinet | PCS | 1 |

| B-3 | buffer storage tank | 2000L | material is SUS304,insulation,with decentration agitator,conical

head,sealed manhole,breather vent,simple valve,digital show

thermometer,plate anti vortex,adjustable legs | PCS | 1 |

| B-4 | Milk pump | 3T/H | SUS304 stainless steel, pump lift is 24 meters, mechanical seal | Set | 1 |

| C | Sterilization & Filling unit |

| C-1 | Tubular sterilizer | 1-1.25T/H | SUS304 stainless steel, aseptic tye, tubular type, inlet

temperature 5℃, sterilization parameters:137℃,4S,output temperature

10-20℃,PLC automatic control | Set | 1 |

| C-2 | Full-automatic

vacuum degasser | 1-1.25T/H | Full-automatic control, SUS304 stainless steel, differential

pressure transducer imported from Germany Labom, working vacuum

degree -0.64~-0.85Kpa, flow control is frequency converted type,

working together with sterilizer, with condensing device | PCS | 1 |

| C-3 | High pressure homogenizer | 1-1.25T/H |

25MPa, including starting cabinet, frequency conversion control | PCS | 1 |

| C-4 | Aseptic pouch filling machine | | one head,4500pcs/hour, 250ml/pcs | PCS | 1 |

| C-5 | belt conveyor | | material SUS304, length 4m | PCS | 1 |

| D | CIP system |

| D-1 | Semi-automatic CIP system | 3×0.8T | SUS304 stainless steel, conjoined structure with single cleaning

way, concentrated acid/alkali tank adding system based on US

technology, temperature automatic control, 50L×2 acid/alkali

concentrate tanks | Set | 1 |

| D-R | CIP return pump | 20T/H | SUS316L stainless steel, pump lift is 24 meters, mechanical seal | Set | 3 |

| E | ACCESSORY EQUIPMENTS |

| E-1 | chiller | | air-cooled compressor,with F22 as chilling medium, 20000Kcal, with

ice water tank and ice water pump | pcs | 1 |

| E-2 | steam boiler | Q=500Kg/h | coal-burning type, steam pressure 8bar, with water treatment and

dust remover | pcs | 1 |

| E-3 | air compressor | Q=1m3/min | screw type air compressor, include air storage tank, cold drier

unit etc | pcs | 1 |

| E-4 | RO water treatment system | 2T/h | including sand filter, carbon filter, ion exchange,one stage RO

system, automatic control | SET | 1 |

| E-5 | water tank | 5000L | SUS304, single layer | SET | 2 |

| F | Installation part |

| F-1 | Stainless steel piping system | | Including CIP system and all product pipe line of whole preparation

unit up to filling part, SMS standard, ¢63, ¢51, ¢38 | Set | 1 |

| F-2 | Power piping system | | Power pipe line of whole preparation stage till filling part, not

include heat insulation | Set | 1 |

| F-3 | Electric controling box | |

Control all equipments of whole preparation stage up to filling

part | Set | 1 |

| F-4 | Electric installation material | | Electric installation material of all equipments of whole

preparation stage up stoped at filling part | Set | 1 |

| F-5 | Mounting and debugging fee | |

Domestic mounting and debugging of all machines offered by Beyond

(if out of China, the buyer should pay the round-air ticket fee and

road cost , the food and hotel fee person per day for subsidy) | Set | 1 |

Principle of milk powder production line

We preheat the pre concentrate with "cow" water and other available

energy sources.

Then, we use hot water to further heat it to the evaporation

temperature.

Condensed steam or "cow" water is cooled by the incoming pre

concentrate.

Next, the highly concentrated substance is directly sent to the

high-pressure pump related to the spray drying operation.

In the mixture tank, the mixture can be pasteurized and cooled to

the batching temperature before the final secondary ingredients are

added manually. The mixture is pumped through a mass flow meter to

a nozzle located in the "high care drying zone".

Service flow chart

Benyou Machinery focuses on the design and manufacturing of the milk powder

production line. Our professional technical engineers can provide a

full set of milk powder production line design solutions, customize

the full set of equipment for the milk powder production line

according to the actual situation of customers, ensure that the

production capacity of the milk powder production line fully

matches the needs of customers, and let customers get the maximum

return with the least investment.